About Us

YS LOCKER Industrial Co., Ltd

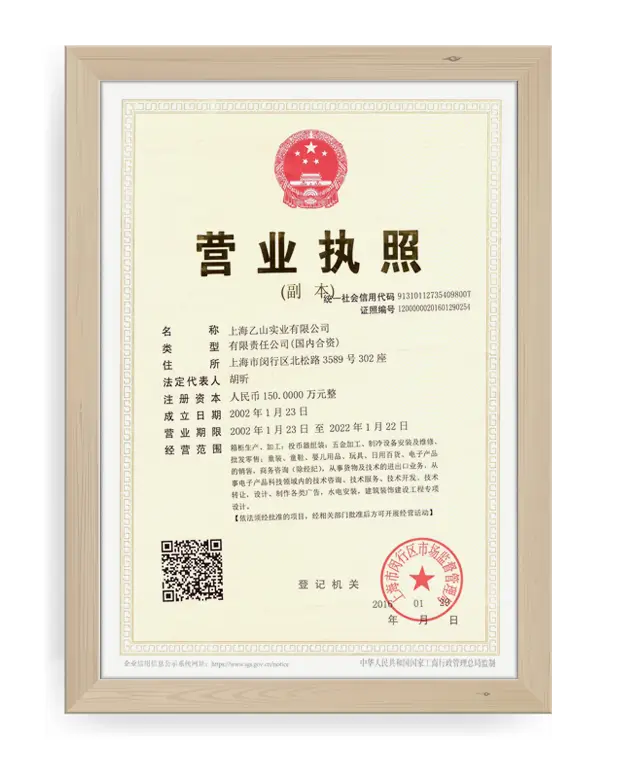

YS Locker is an IoT company established in 2002, headquartered in China. We focus on the R & D, design, production, sales and operation of intelligent devices, terminals and management service software, providing integrated solutions for multiple industries.

Our products include intelligent lockers, vending machines, coffee machines, delivery robots, front-integrated warehouses and other service equipment, widely used in water parks, theme parks, enterprises, schools, communities, shopping malls and other places. Our solutions are well received by users for their safety, convenience and versatility.

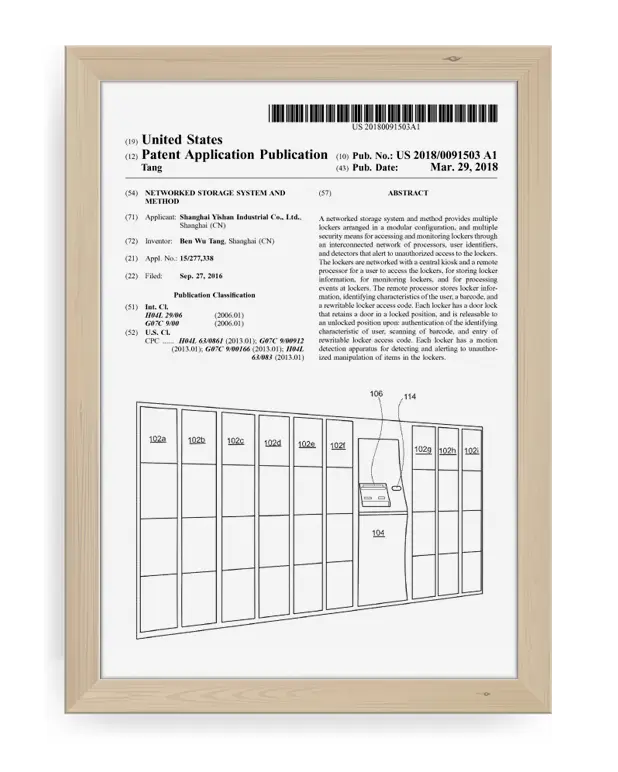

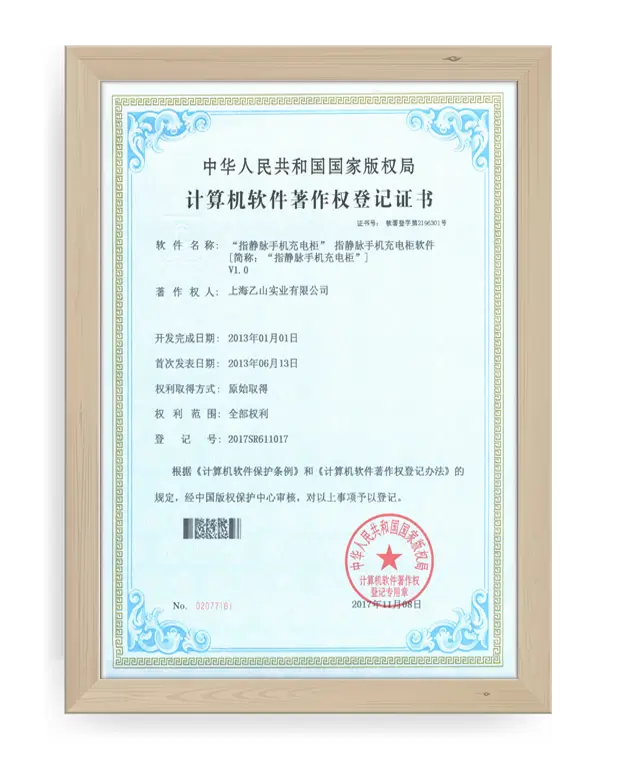

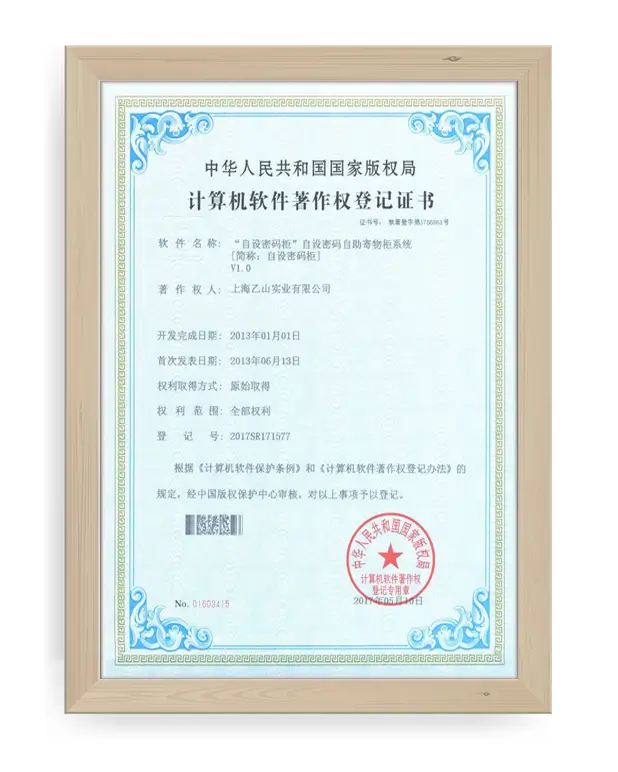

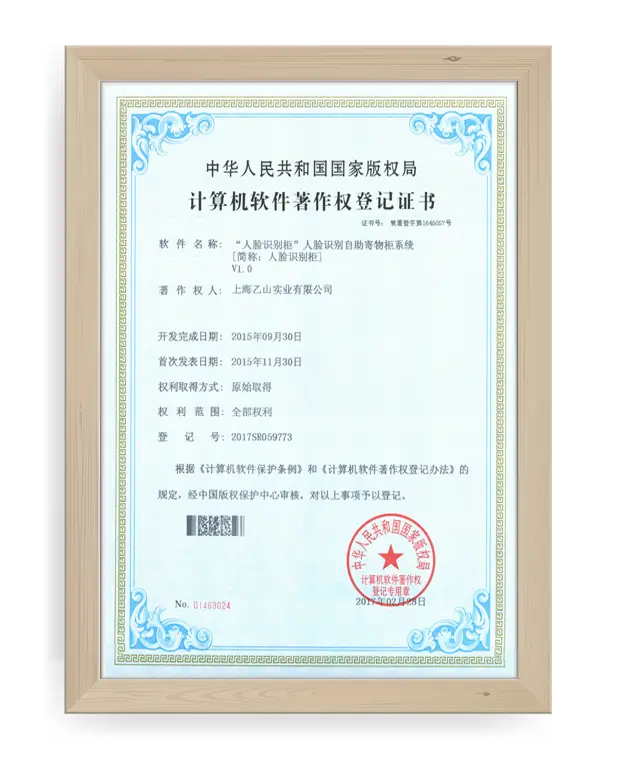

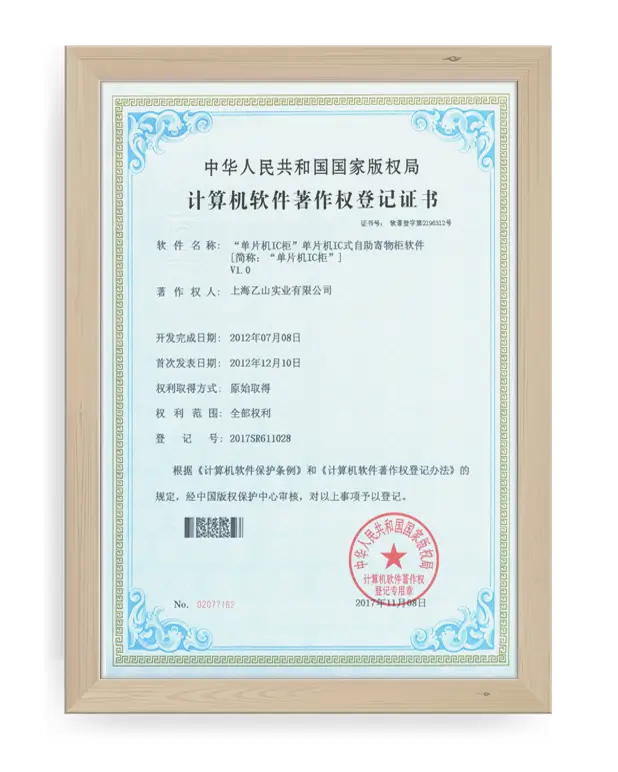

Our team consists of doctors, postgraduates, undergraduates, etc., with rich industry experience and professional knowledge. We focus on R & D investment, and R & D expenses account for 12-15% of annual sales, with a number of invention patents and software copyrights.

Our customers include many Fortune 500 companies, and we provide customers with customized system development services and become first-level suppliers to customers. Our products and services have covered many countries and regions around the world, providing customers with multi-faceted support and services.

Why Choose Us

01.

Award-Winning Expertise

With over 23 years in the industry, YS Locker delivers top-tier software and locker management solutions.

02.

Effortless Management

YS Locker’s Smart Locker software saves time and resources. No manual setup or removal of inactive accounts needed.

03.

Custom Design Flexibility

Our multidisciplinary team provides flexible customization to meet your unique requirements.

04.

Modular & Scalable

YS Locker’s proprietary software adapts to your specific workflow and integration needs.

05.

Dynamic Insights

Benefit from powerful, real-time monitoring, reporting, and management capabilities.

06.

Versatile Operation

Choose between a standalone system or a fully networked platform with centralized enterprise control.

YSLOCKER History

Origins

1997

The predecessor Yishan Air Conditioning Equipment was established in Shanghai

Birth

2002

Yishan Industrial was born Founded in Shanghai and began to produce lockers

Electronic Age

2008

Products entered the electronic age and Yishan’s first electronic terminal equipment was launched on the market

Entering Asia

2013

Developing the Asian market and entering the Southeast Asian region, the company is located in Kuala Lumpur

Setting Sail

2016

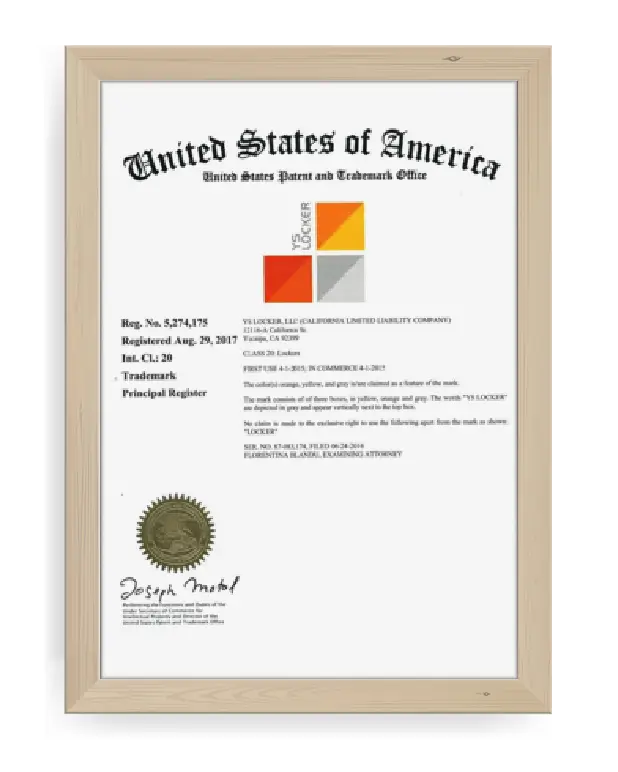

Officially opening the overseas market, the US company was established and the company is located in Los Angeles

Expansion

2018

Turning to enter the European market At this time, Yishan is moving towards the international era

Honor

2020

Through our years of accumulated strength, we applied for and obtained a national certificate, a high-tech enterprise

Listing

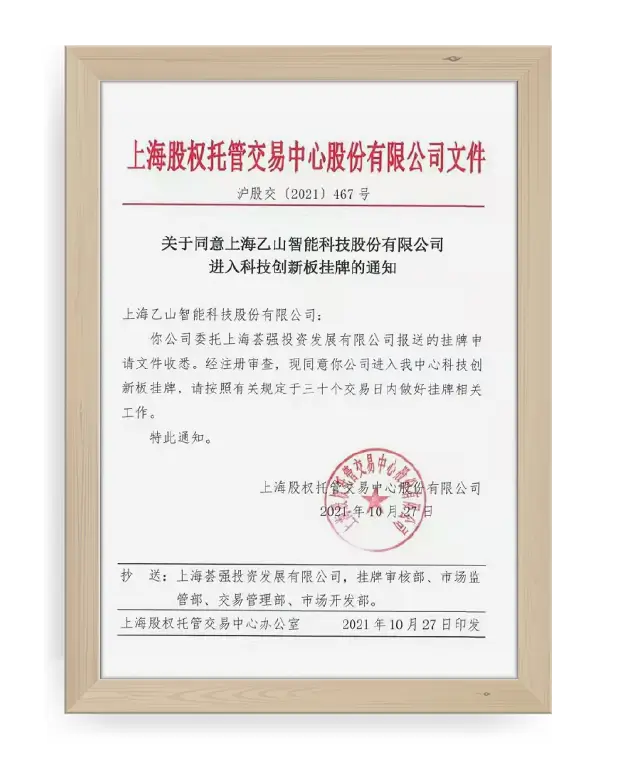

2021

Listed on the Science and Technology Innovation Board, preparations before listing, the establishment of a smart hotel operation company

Brand

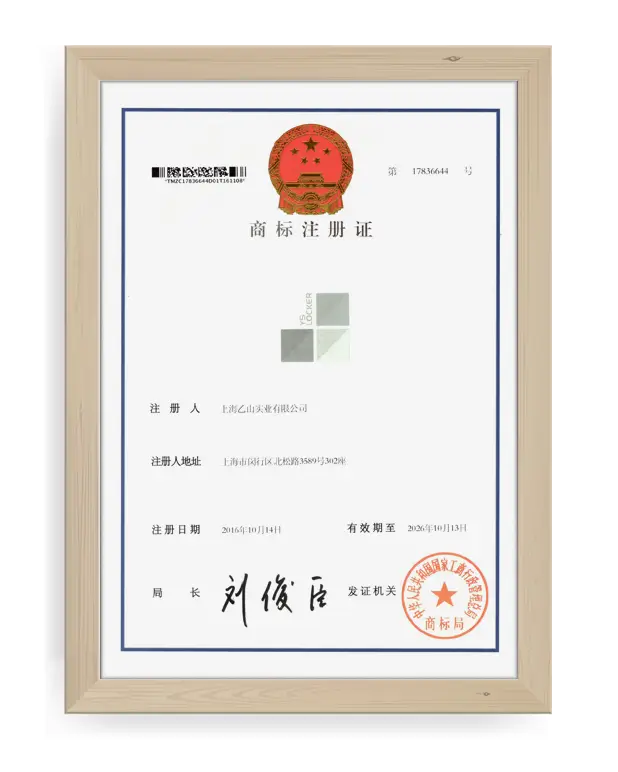

2023

YS Locker has transformed from a traditional manufacturing industry to a brand operator

YSLOCKER Factory

From design to production: How YS factory shapes high-quality lockers

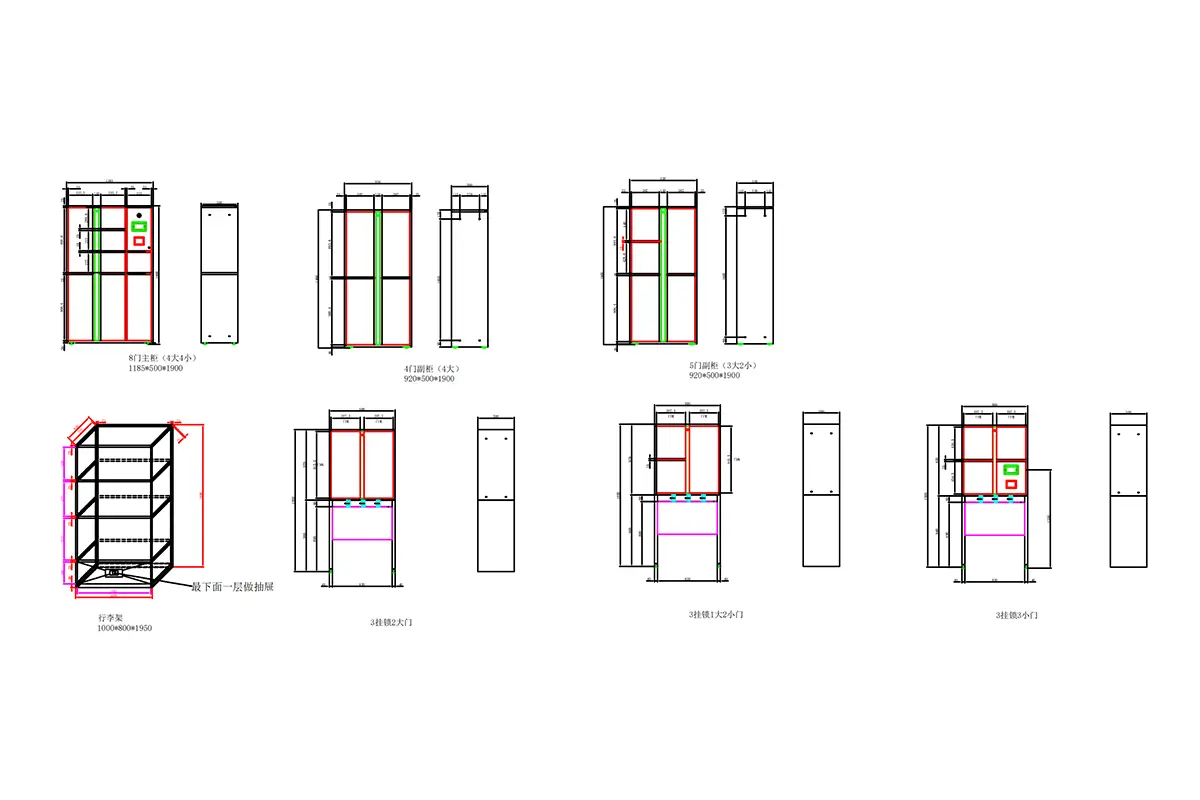

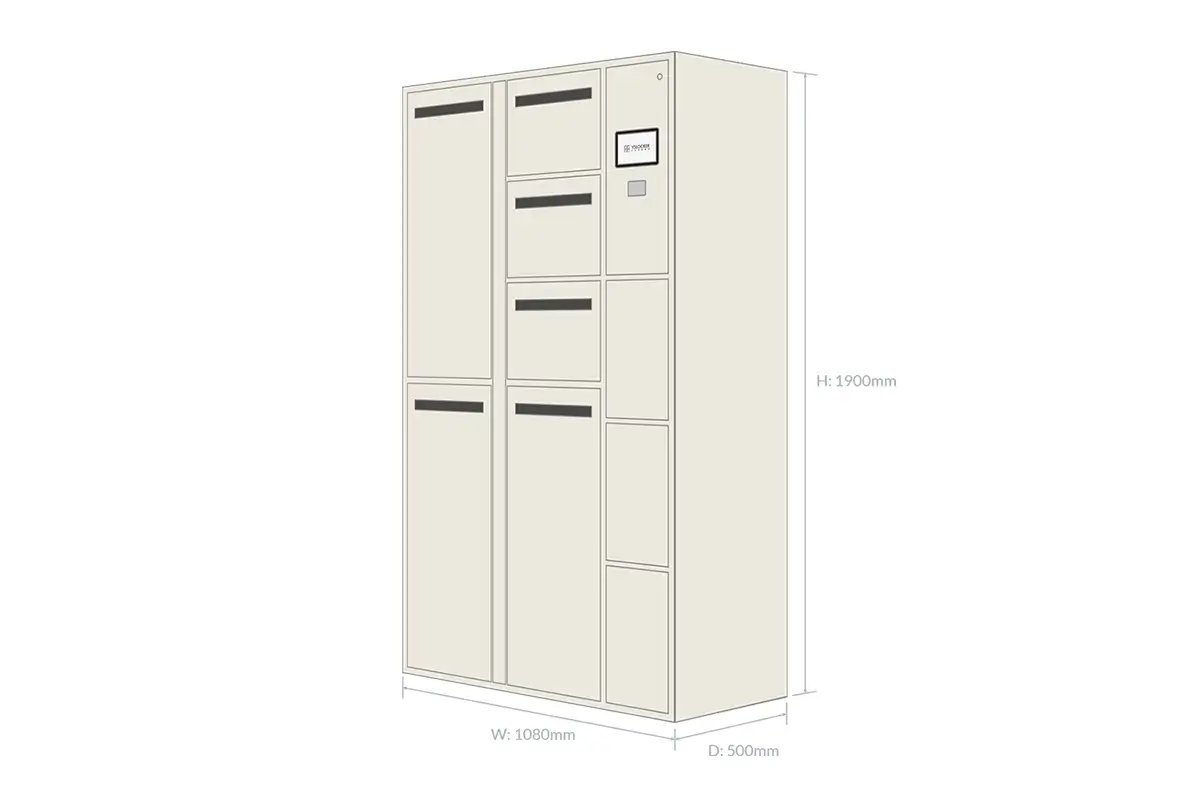

Smart Locker Design Process

The design process for YS Smart Locker begins with understanding your specific needs. We work closely with you to develop a solution, ensuring the design is optimized for usability, durability, and functionality. High-quality production is achieved through advanced CAD modeling and software analysis.

This initial step involves understanding the client’s specific needs and expectations. We collect detailed information on smart locker design specifications, functionality, and appearance. Clear communication ensures our team fully grasps the project’s purpose, guiding the design process to achieve desired outcomes.

Based on the collected requirements, we tailor a locker solution to meet specific needs. We refer to on-site construction drawings to determine the plan, including locker materials, dimensions, colors, and display screen sizes. Simultaneously, we aim to achieve goals of usability, functionality, and cost-effectiveness, creating a solution that fulfills client operational needs and enhances user experience.

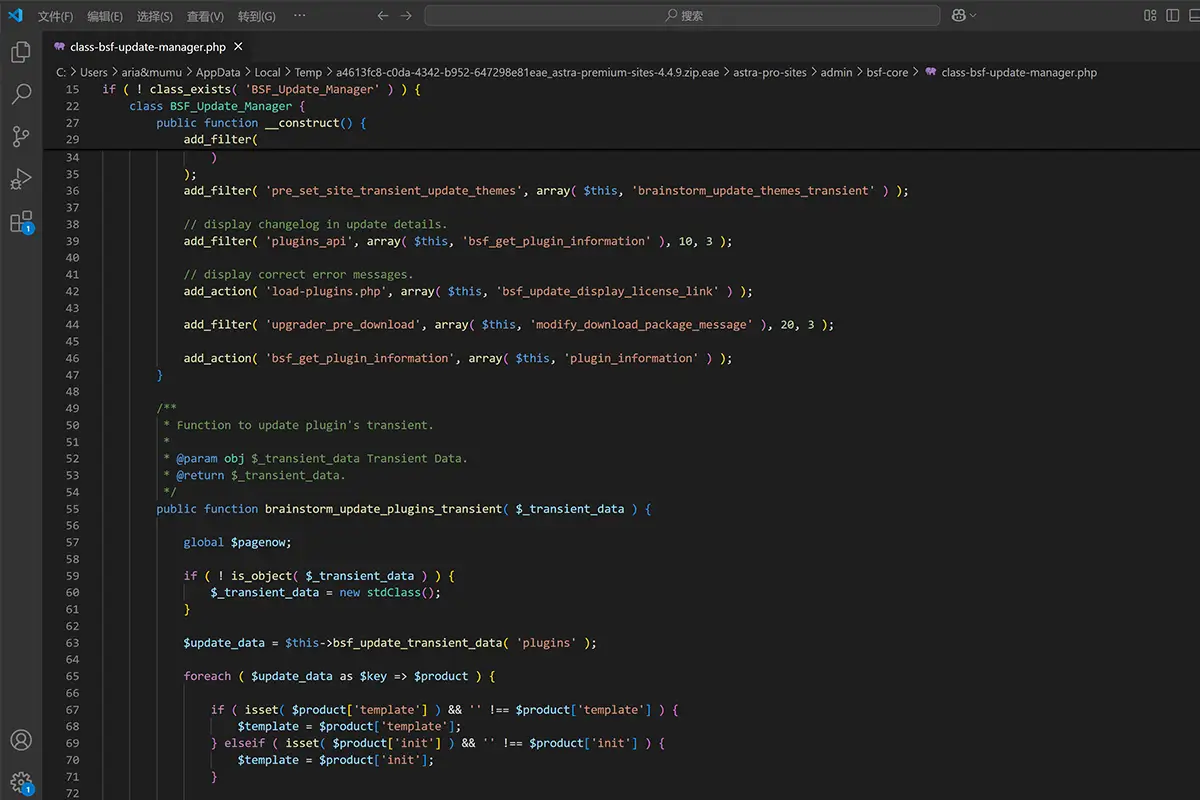

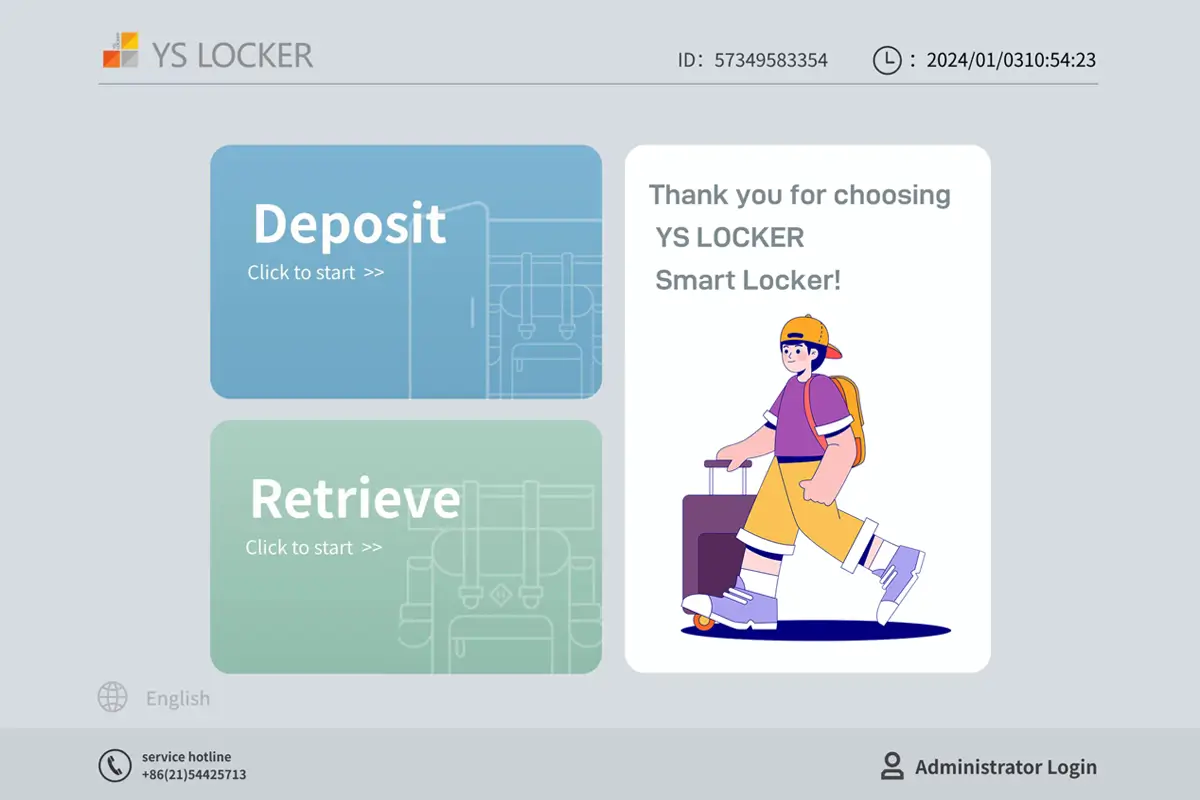

At this stage, we develop and integrate the software components required for the smart locker system. This includes user authentication, access control, remote management, and data analysis. Our team ensures seamless compatibility between hardware and software, enabling smooth operation and providing clients with a comprehensive management platform or seamless data integration with their backend systems.

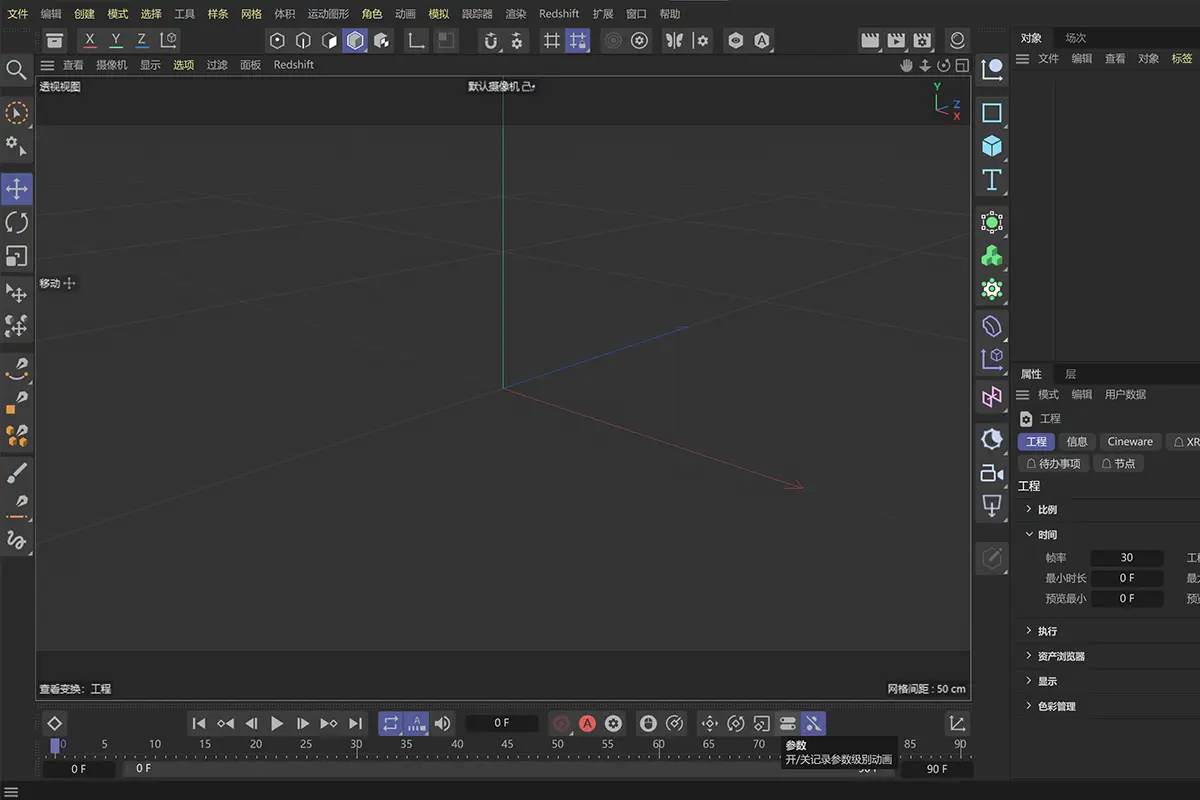

Using advanced design tools, we create detailed 3D models of the smart locker. This virtual blueprint allows for precise visualization of the structure, dimensions, and functionality. Subsequently, we develop 3D scene models to evaluate real-world performance, providing valuable insights into usability, durability, and aesthetics.

The model undergoes rigorous simulation to identify areas for improvement. We analyze performance, security, and usability to optimize the design. This iterative process ensures that the final product meets all functional and aesthetic requirements of the client, delivering a reliable and efficient smart locker solution.

Once the final design is confirmed, we develop a comprehensive production plan. This includes materials, manufacturing processes, and quality control measures. Through careful planning, we ensure efficient production, consistent quality, and timely delivery of the smart lockers, while also preparing for deployment.

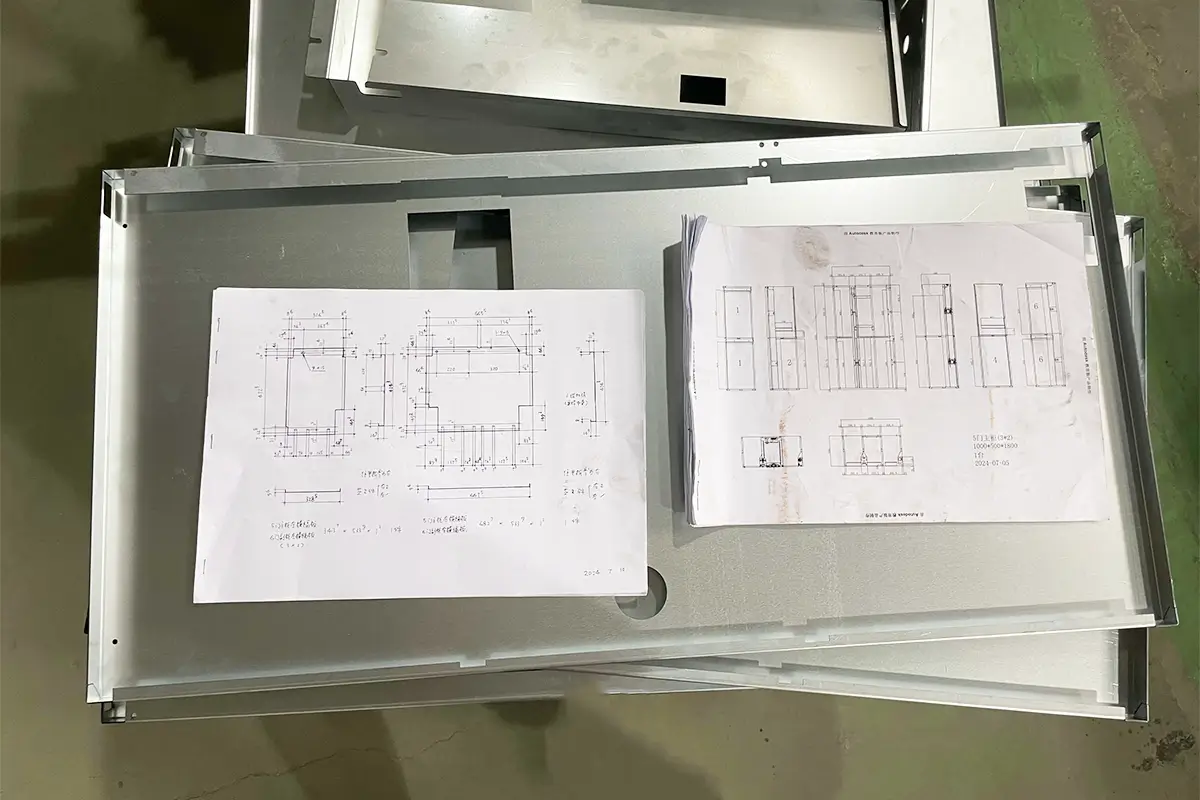

Smart Locker Production Process

After the design is completed, our production process begins. Utilizing standardized procedures and mature technology, we transform the design into high-quality smart lockers. Every step of the process is carefully monitored to ensure the product meets stringent quality standards and exceeds your expectations.

After the design drawings of the locker arrive at the factory, our engineering team conducts a detailed review to ensure that all dimensions, specifications, and functional requirements are accurate. This step lays a solid foundation for subsequent production, ensuring that every process is strictly executed according to the design.

Based on the design drawings, we carefully select suppliers for components, including panels, hardware accessories, and electronic elements. All materials undergo rigorous inspection to ensure they meet standards for strength, durability, and safety, providing reliable assurance for the manufacturing of smart lockers.

Using advanced CNC laser cutting equipment, we precisely cut the panels according to the design dimensions. This process ensures that each panel's size and shape fully meet the requirements, preparing for subsequent bending, drilling, and welding processes.

Using a bending machine, we shape the cut panels according to the design drawings. This step ensures the locker's structure is sturdy while meeting the streamlined requirements of the exterior design, enhancing overall aesthetics.

On the bent and shaped panels, we use drilling equipment to create precise holes. These holes are designed for installing electronic components, locks, and other functional accessories, ensuring the functionality and assembly efficiency of the smart locker.

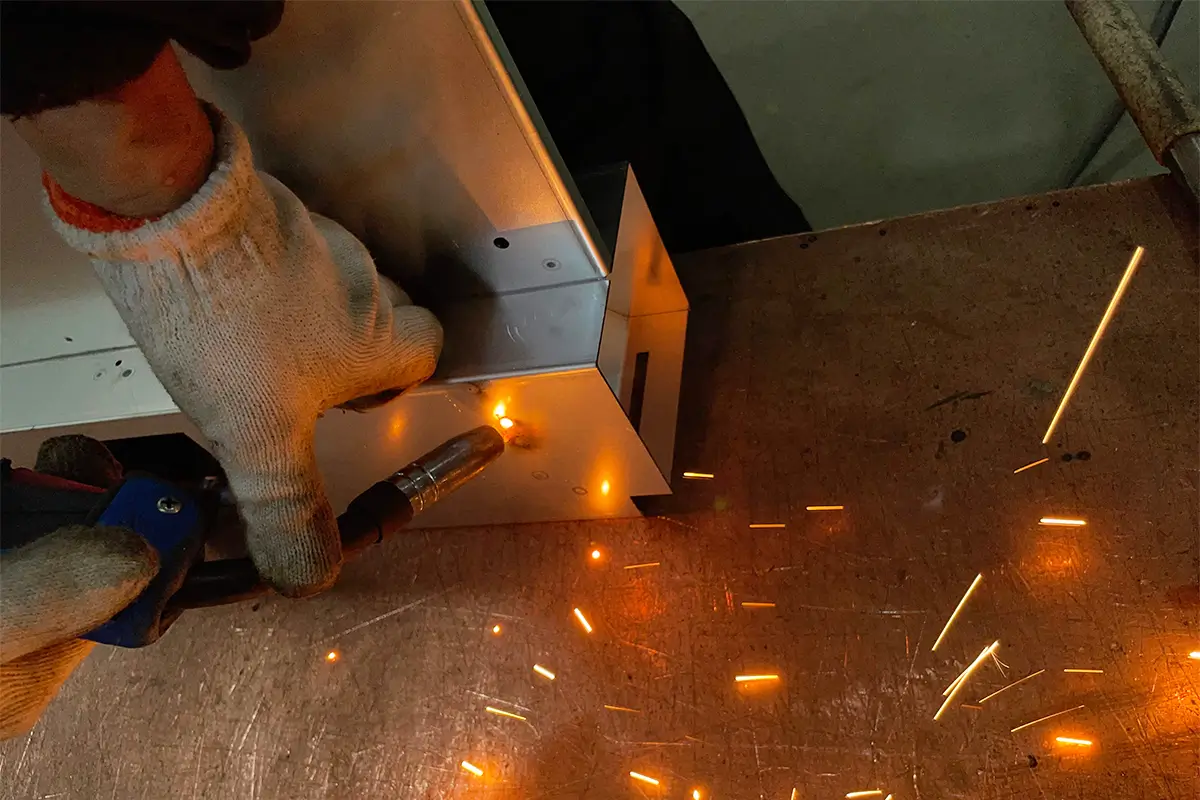

Our experienced welding team assembles the panels by welding, ensuring the firmness and stability of each connection point. We employ cold welding technology to guarantee the overall strength and durability of the locker.

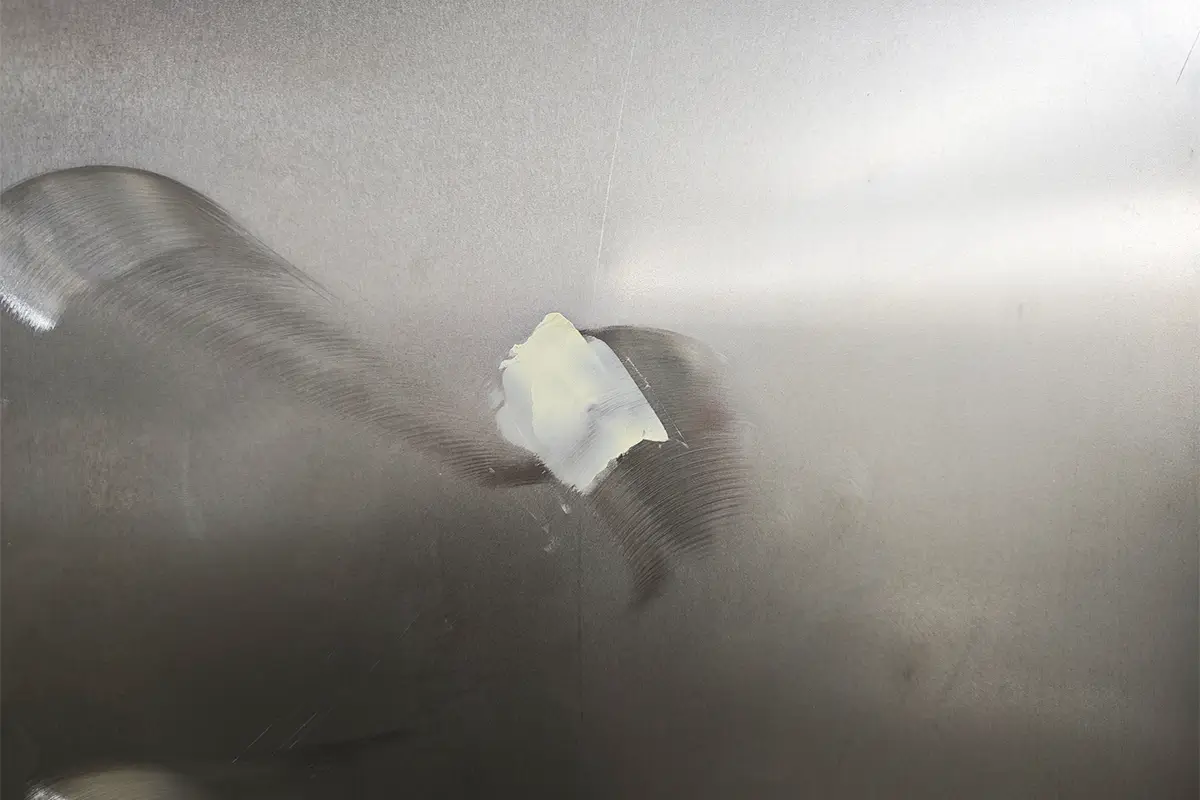

After welding is completed, we meticulously refine the welding points, removing burrs and uneven sections, a process we refer to as "da ni zi." This step not only enhances the locker's exterior quality but also ensures user safety during operation.

Finally, we apply powder coating/painting to the lockers, using selected coatings to ensure durability and aesthetics. The powder coating/painting process covers all details, including the base, front, and protective layers, providing the smart lockers with rust-proof, corrosion-resistant, and wear-resistant properties, while also meeting the client's requirements for exterior color.

Smart Locker Installation and Packaging Process

Quality is at the core of everything we do. Our comprehensive quality control process includes multiple stages of inspection and testing to ensure that every smart locker meets the standards. From measuring dimensions to visual inspections, we ensure that each locker is durable, precise, and fully functional for its intended applications.

During the inspection phase, we first conduct a thorough check of the locker's surface to ensure that the powder coating/painting is even and free of flaws, and that the welding points are smoothly refined. The overall appearance must meet the design standards. This step guarantees the locker's aesthetic appeal and durability, satisfying the client's high expectations for exterior quality.

We use measuring tools to conduct a comprehensive check of the locker's final dimensions, ensuring that each component's size fully matches the design drawings. This step guarantees the structural precision of the locker, laying a solid foundation for subsequent hardware assembly and on-site locker installation.

Our experienced assembly team installs locks, display screens, and other functional accessories onto the lockers. We strictly adhere to operational standards, ensuring that each component is securely and reliably installed, thereby guaranteeing the functionality of the smart lockers.

After the hardware assembly is completed, we install customized software systems for the smart lockers, including user authentication, access control, and remote management functions. Our technical team ensures seamless compatibility between software and hardware, guaranteeing accurate data transmission/statistics, to achieve intelligent operation and efficient management.

Before shipment, we conduct comprehensive functional tests on the smart lockers, including lock operation, software performance, and display screen calibration. This step ensures that each locker operates stably, meeting the client's requirements for functionality, security, and ease of use.

After passing the final tests, we professionally pack the smart lockers using shockproof and moisture-resistant materials, with wooden pallets for added protection, ensuring they are not damaged during transportation. We arrange logistics according to the client's requirements, ensuring the lockers are delivered safely and on time to their destination, ready for on-site installation.

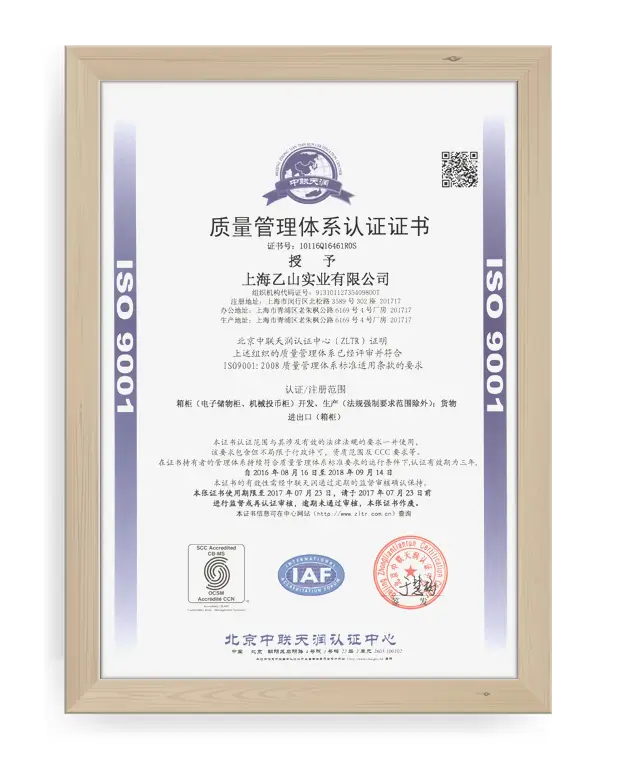

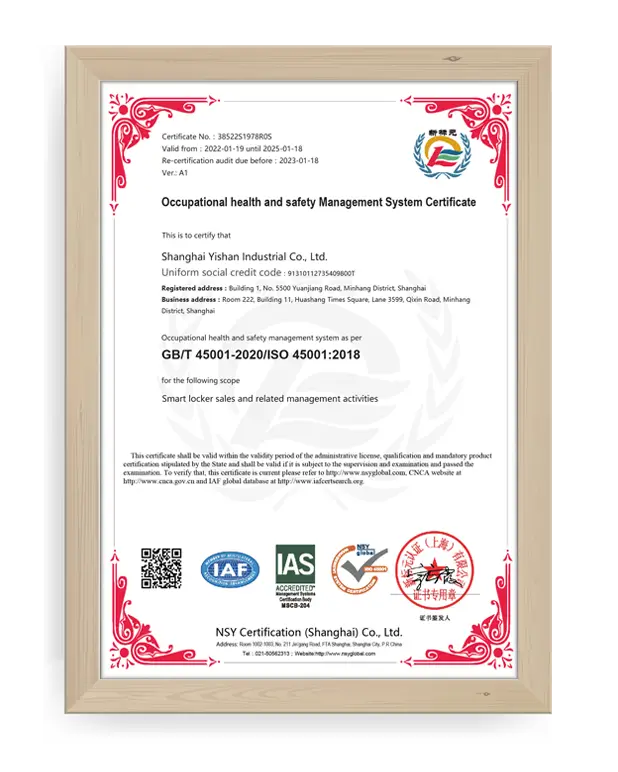

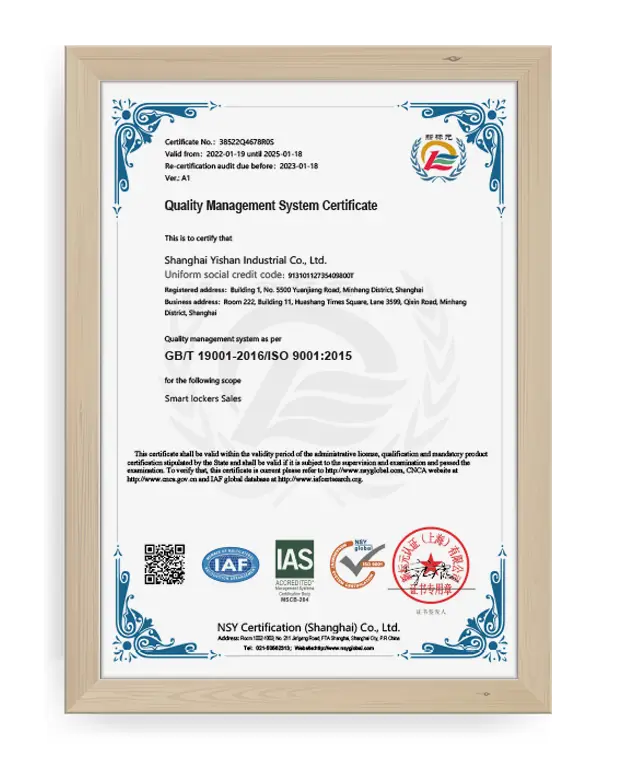

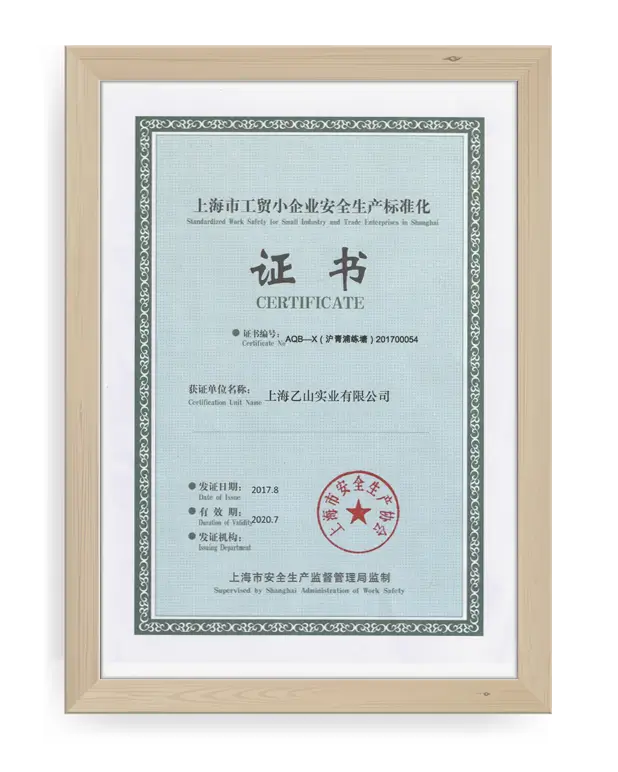

YSLOCKER Qualifications

Rigorous standards and certifications: How YS ensure excellence in every product

Unlock Your Dreams

YSLocker offers 24/7 ongoing global support, ensuring we’re there for clients whenever needed.